Supply Chain Management or SCM

Supply Chain Meaning and Definition:

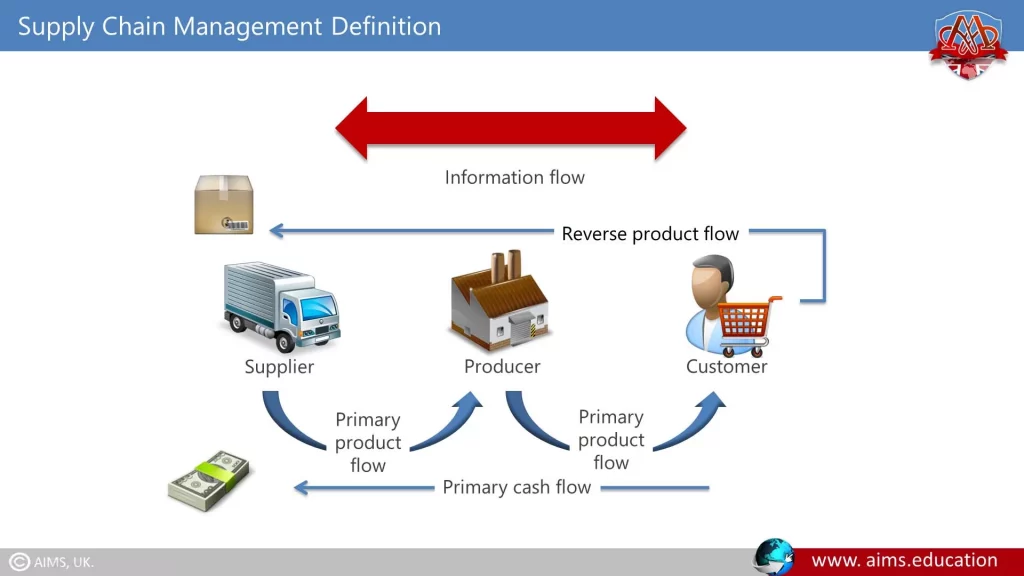

Here is the meaning and definition of supply chain management in simple words. “A supply chain is the management of a network, which is used to deliver products and services, from raw material to the customers, through physical distribution, the flow of information, and cash”. It comprises a network of both processes and entities. In a basic supply chain, there are three entities: Producer, Supplier, and Customer. These entities that perform the processes can be businesses or governmental organizations or individuals. A supply chain doesn’t have to be global, but the massive chains that interest us in this course are the ones that run through corporations, and are decidedly global in scope.

What is Supply Chain Management?

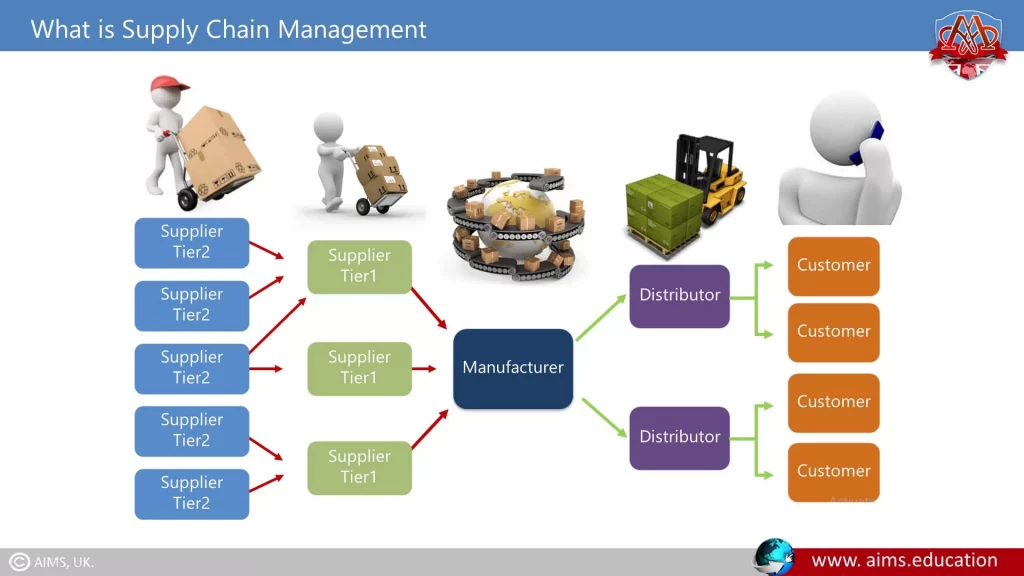

As mentioned above, a supply chain needs only three entities to exist. The three entities in the supply chain processes can be departments or functional areas or individuals within a larger organization; there are internal as well as external supply chains. For the most part, the model applies to corporations. Most work on supply chains, both theoretical and applied, involves a manufacturing firm in the middle (although service firms also have supply chains) with a supplier of materials or components on the upstream side and a customer on the downstream side. The three organizations of the supply chains, that is Supplier, Producer, and Customer are explained here:

Entity-1 Supplier:

It is a provider of goods or services or a seller with whom the buyer does business, as opposed to a vendor, which is a generic term referring to all sellers in the marketplace. The supplier provides materials, energy, services, or components for use in producing a product or service. These could include items as diverse as sugar cane, fruit, industrial metals, roofing nails, electric wiring, fabric, computer chips, aircraft turbines, natural gas, electrical power, or transportation services.

Entity-2 Producer:

It receives services, materials, supplies, energy, and components to use in creating finished products, such as dress shirts, packaged dinners, airplanes, electric power, legal counsel, or guided tours. (Note that SCM for services may be more abstract than those for manufacturing).

Entity-3 Customer:

Receives shipments of finished products to deliver to its customers, who wear the shirts, eat the packaged dinners, fly the planes, or turn on the lights. This lecture is a fundamental part of the online mba in logistics and supply chain management degree program and the online supply chain management diploma. All these programs are offered online and they are also the pre-requisite for the research-based doctorate in logistics and supply chain management.

Supply Chain Structure:

An organization’s SCM or network can have many forms, for both, local and the global supply chains. It can be a simple supply chain structure with a single strand, a complex network, or any structure between those two extremes. No matter whether it is a product or service chain, or what types of entities are involved, companies require their SC to guarantee a steady flow of supply while at the same time striving to reduce their SC costs. They can improve operating efficiency by employing the right structure.

Supply Chain Management Costs:

Depending upon the type of industry, supply chain costs can be as high as 50% of a company’s revenues. According to research done by A. T. Kearney, a global consulting firm, inefficiencies in the SC can total 25% of a firm’s operating costs. When a company is faced with thin profit margins, like 3% to 4%, even a small improvement in efficiency can double profitability. Implementing the appropriate cost-centered structure and strategy is critical.

Supply Chain Management Strategies:

There are three main types of supply chain management strategies: Stable, Reactive, and Efficient Reactive:

- Stable: With a significant history of stability between demand and supply.

- Reactive: These are focused on execution, efficiencies, and cost performance.

- Efficient Reactive: That uses simple connectivity technologies and has little need for real-time information.

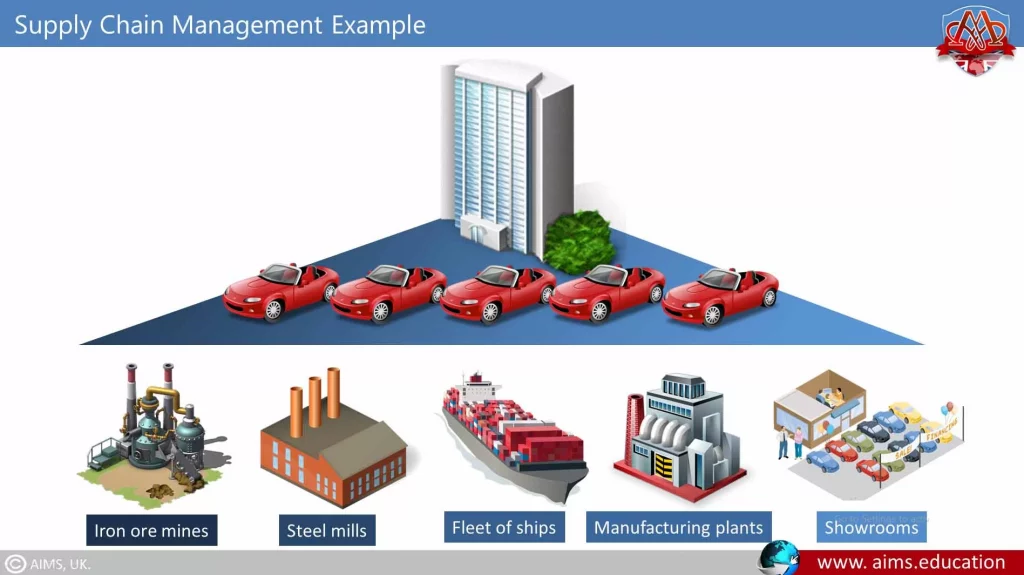

Supply Chain Management Examples:

Consider, as a very simplified instance of this stripped-down SC model, a young street vendor who sells just a few light snacks. This is a familiar sight on warm summer days around the globe, whether it is fresh crepes in Paris, roasted chestnuts in New York, or small servings of spicy tapas in South America. In many ways, the food vendor on the street resembles small family businesses that exist in cities all across the world.

This simple street vendor represents one end of a supply chain. The supplier is probably a small wholesale food distributor that sells basic ingredients to many ones- or two-person food kiosks. The worker is the “producer” who turns the raw ingredients into crepes, roasted nut mixes, or a variety of easy-to-cat tapas. The stand, operated by one or two owners, is the retailer that sells the finished delicacies to the customers or passes by who is cajoled into making a purchase.

Complexities in Simplest Supply Chains:

Notice that even in this simplest of supply chains, the basic model needs amplification. For instance, there are more suppliers than one. While flour and nuts may be procured from the same supplier, water to warm the stainless steel food containers comes from the employee’s kitchen facet, and the supplier of that water may actually be a government entity rather than another business. Electricity is supplied to light this mini “manufacturing center.” Nearby is a food preparation area with refrigeration for storing the perishables needed plus shelves and drawers to hold various basic supplies, such as tongs and other utensils. There is also wood to build the stand and a whiteboard and markers for making signs to advertise the day’s offerings. Somewhere in the chain, though they remain invisible in our model, are suppliers’ suppliers, who bring materials, components, or services to the food wholesaler and the utility companies.

Types of Supply Chain Management:

SCM in Manufacturing:

Discussions of supply chains typically put manufacturing at the center and suppliers of components to the immediate left. It may be that component suppliers are the most crucial consideration when designing and managing an SC for manufactured products, but utilities and other services are not inconsequential contributors to the cost of operations.

EXAMPLE OF A FOOD VENDOR:

In the case of our food vendor on the street, services most obviously include utilities, transportation, warehousing, carpentry, and cleanup, among others. Utilities, which are suppliers to all manufacturers, are crucial considerations when locating plants and warehouses. If water and electricity (or natural gas, or both) are not available at a proposed site, they cannot be readily made available.

TIER-1 AND TIER-2 SUPPLIERS:

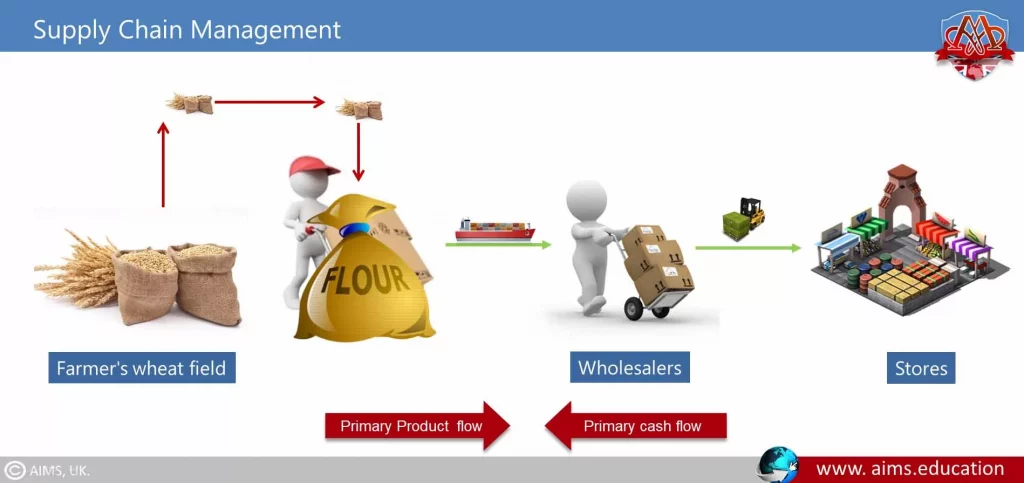

Tier 1 suppliers have their own suppliers in Tier 2. The wholesale food distributor that supplies the daily ingredients and raw materials for the menu items has its material and service suppliers—and they have their suppliers, and so forth. The flour for the crepes, for instance, is not raw material but a product with its own SCM that begins in a farmer’s wheat field and is processed in a plant, shipped to a wholesaler, and distributed to the corner store. No matter how far you travel toward the left, you will never run out of new tiers of suppliers.

EXAMPLE OF A COAL MINER:

Even a raw material extractor, such as a coal mine, has its own suppliers of extraction machinery and services. In fact, the coal mine may ship coal to a generating plant that supplies power to the manufacturer that produces a machine that is shipped to a distributor that sells mining equipment to the same mine that began the process; supply chains can double back on themselves. (A distributor is a business that does not manufacture its own products but purchases and resells these products).

Supply Chain Management – In Services:

Although the traditional supply chain management model was developed in manufacturing, the service industry, too, has supply chains. According to the A PICS Dictionary, 13th edition, a firm in the service industry is “in its narrowest sense, an organization that provides an intangible product such as medical or legal advice.” In its broadest sense, service industries include “all organizations except farming, mining, and manufacturing. It includes retail trade; wholesale trade; transportation and utilities; finance, insurance, and real estate; construction; professional, personal, and social services; and local, state, and federal governments.”

SERVICE-ORIENTED SUPPLY CHAIN ALSO REQUIRES SOPHISTICATED MANAGEMENT:

The supply chain of an electric utility, receives products, services, and supplies of its own and dispenses its services into three distribution channels: home customers, commercial customers, and other utilities.

The flows in our street vendor example aren’t quite as simple as might be supposed, either. The “products” that move through the chain could include materials, supplies, and the components used in the production of the menu items. Information flows may be fairly rudimentary orders submitted by end users (caters) of the product, by the distributor (the person on the street with the cart) to the manufacturer (the person who assembles the ingredients), and by the manufacturer to the supplier (the source of the food). There will be recipes and shopping lists, discussions of potential demand, and perhaps records of last year’s results. The flows of cash may be based upon the information contained in the cash register or credit card receipts.

CASH TRAVELS:

It travels separate flows from the manufacturer to suppliers of products and services and, of course, to any lenders or investors for debt or dividend payments.

- There are also logistics management concerns: Transportation from one entity to the other – perhaps drawing upon the private fleet of a car or two – as well as the warehousing decisions. And finally,

- The reverses SCM exists to return any unacceptable menu items, recycle the vegetable waste into a composter, reuse utensils, and other supplies after sterile cleansing, and dispose responsibly of any packaging.

Starting a Supply Chain Business:

Many global businesses began in someone’s home office, garage, or basement with the glimmering of an idea for, let us say, a computer operating system or a new idea for consumer-to-consumer e-commerce. Perhaps the food vendor comes up with a new twist on the old recipe for crepes; a customer is impressed and asks if the vendor can make 50 crepes for a lunch-time birthday celebration at his nearby office; someone at the birthday lunch owns a neighborhood restaurant…and before long the vendor has rented space in a small commercial kitchen facility to supply special made-to-order crepes for local businesses within a few blocks. It’s surprising how many challenges and opportunities can be anticipated and can be seen most easily in a very simple model.

Summing Up:

There are many variations in the supply chain management processes, supply chain partners, supply chain management models, and supply chain demand management. Here are some basic points to keep in mind as the discussion continues and grows more complex.

- SC involves, directly or indirectly, everyone and everything required to extract materials, transform them into a product, and sell the product to a user.

- Supply chains include various entities, such as raw material extractors, service, and component suppliers, a material product manufacturer or a producer of services, distributors, and end customers.

- SCM structures vary based on demand history, business focus, and needs for connectivity, technology, and equipment.

- Supply chains can be viewed in terms of processes, such as the gathering and processing of marketing data, distribution and payment of invoices, processing and shipping of materials, scheduling, fulfillment of orders, and so forth. Such functions cut across entities.

- Supply chains include various flows as well as various entities. Materials and services flow from suppliers toward customers; payment flows from customers toward suppliers; information flows both ways. Supply chains also run in reverse, starting with the customer who sends back such items as components for replacement or repair, returned goods for re-manufacture, and obsolete goods for recycling or disposal. The reverse chain, like the forward chain, also comprises information flows and cash or credits.

Future of Supply Chains:

SCM expertise is so important in today’s business world that an annual survey is conducted to identify the 25 best supply chain leaders based on specific criteria. It’s a major accomplishment to be named to that list and an even higher compliment when a company manages to remain in that top echelon of supply chain performers for consecutive years. Check the online Resource Center for a link to those survey results and to see which companies are top-ranked for their SCM expertise.

Original Article – https://aims.education/study-online/what-is-supply-chain-management-definition/